Trinity Cobalt 2

(Source: Trinity)

The

Cobalt 2 can uses the Cobalt style can back . The back of the can

needs to have venting holes to keep the motor cool. Cutting holes

and removing material compromises the magnet's field return path.

Take too

much material away and your magnets get weaker and you loose torque

and efficiency. |

|

The Cobalt 2

has a different hole pattern between the magnets which increases

power on bigger faster tracks with no loss in low end performance. |

|

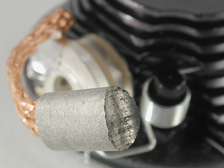

Our

new "Ellipse" brush

system is designed to provide enough surface area to the comm to

deliver the voltage to your armature, yet fire softer to keep the

commutator from burning up. This armature and set of brushes was

ran at the

US Indoor Championships, made the A main, and made 4 runs the following

week in testing with no cuts or changes to the brushes. The commutator

shows no signs of burning nor has it changed color from over heating. |

|

|

|

Trinity was the first company

to ever make an aluminum endbell motor for RC cars. In 1987 Trinity had the Pure Gold series which featured aluminum

finned endbells. We anodized the endbells back then to keep the

capacitor leads from shorting the out the endbell. We sold motors with gold,

orange and clear anodized endbells. |

|